3C electronics is the abbreviation for the three major categories of electronic products: computers, communications and consumer electronics. Due to the fast processing speed, high precision, and small heat-affected area of laser marking machines, which cannot be achieved by many conventional methods, laser marking machines have been used more and more widely in the 3C industry.

1. Process innovation:

3C products are personalized and popular consumer products. Only by constantly creating new highlights in shape and function can they attract consumers. Then users have great expectations for laser processing in product process innovation, especially precision processing. High requirements for optical quality, only fiber lasers and end-pumped lasers can meet the requirements. In contrast, fiber lasers have become the darling of the times due to a wider range of applications;

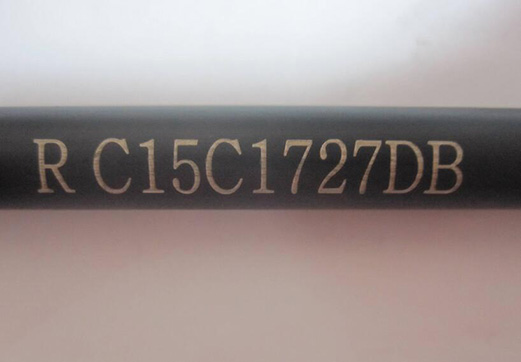

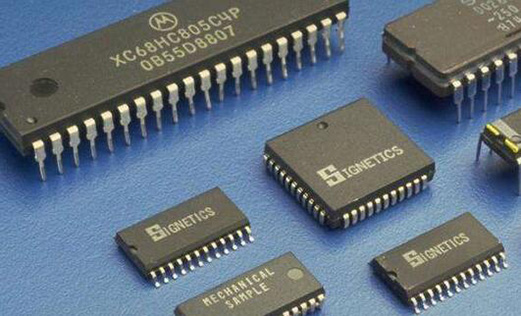

Laser marking pattern on IC electronic material

2. Become the mainstream:

The application of laser technology in the 3C industry has changed from an optional process to the current mainstream application. It has been defined that laser processing must run around the clock like a CNC machine tool. The quality requirements and popularity of the equipment are getting higher and higher, and even a large number of them have emerged. For professional laser processing OEM manufacturers, the mainstream of laser processing requires greater versatility and process forward-looking. Only fiber laser machines have such a huge application potential to be tapped.

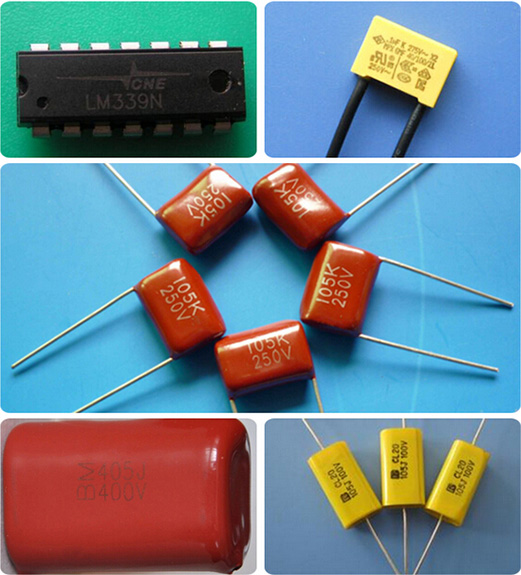

Laser typing samples on resistive electronic materials

3. Scale:

3C manufacturers, especially OEM/EMS manufacturers, are manufacturing-type, and they mainly rely on output to earn benefits. Naturally, they require a large amount of equipment. At present, there are countless 3C manufacturers in mainland China with more than 50 laser equipment manufacturers, which requires equipment failure maintenance frequency Low, low cost, the advantages of fiber lasers are self-evident;