The design of modern kitchen utensils fully considers practicality and aesthetics. Among them, the solid, corrosion-resistant, and beautiful stainless steel materials are favored by many customers as the sheet metal panels of kitchen facilities. With the overall improvement of people's living standards, kitchen facilities Need more professional design, shorter production cycle, more personalized engineering customization requirements.

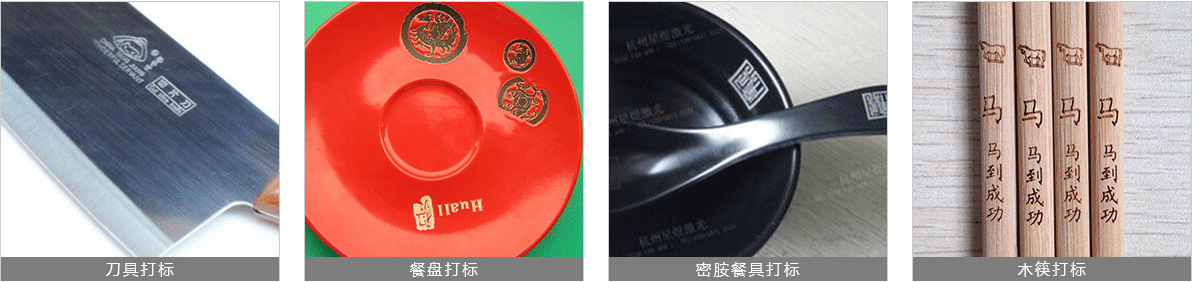

Introduction of laser marking application:

There is no need to touch the material during the laser marking process, and there is no extrusion. Even small kitchen utensils can be easily marked and processed. The small kitchen utensils can also have an exquisite appearance, and the laser marking machine is operated by a computer system, which is simple and convenient to use. The marked pattern is not easy to wear, exquisite and beautiful, and can also play a good anti-counterfeiting effect. At the same time, laser treatment is a harmless element, non-toxic, non-corrosive, and non-chemical, which can ensure a clean working environment and reduce production costs.

Advantages of laser marking in the kitchenware industry:

Laser cutting application introduction:

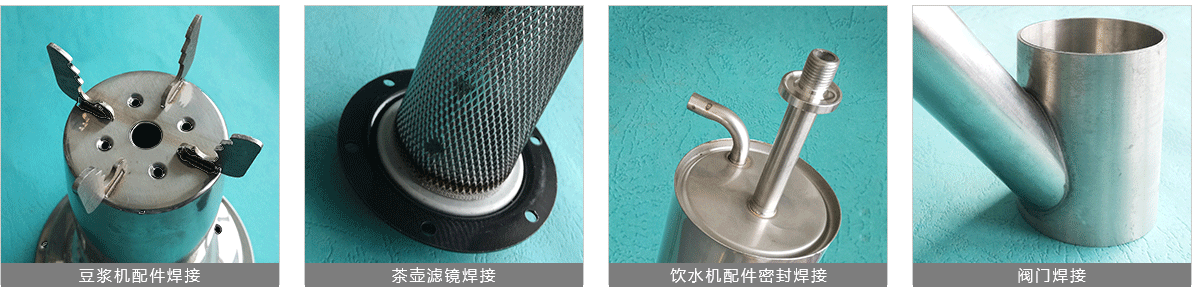

Laser welding has the smallest heat input and extremely small heat-affected zone, which can significantly improve the quality of the welded product while reducing the time for follow-up work. In addition, due to the fast welding speed and large welding aspect ratio, welding efficiency and stability can be greatly improved. Due to the extremely low heat input during laser welding, the amount of deformation after welding is small, and a very beautiful welding surface effect can be obtained. There are few subsequent welding treatments, which can greatly reduce or eliminate the labor cost of the huge polishing and leveling process.

Advantages of laser welding in the kitchenware industry: