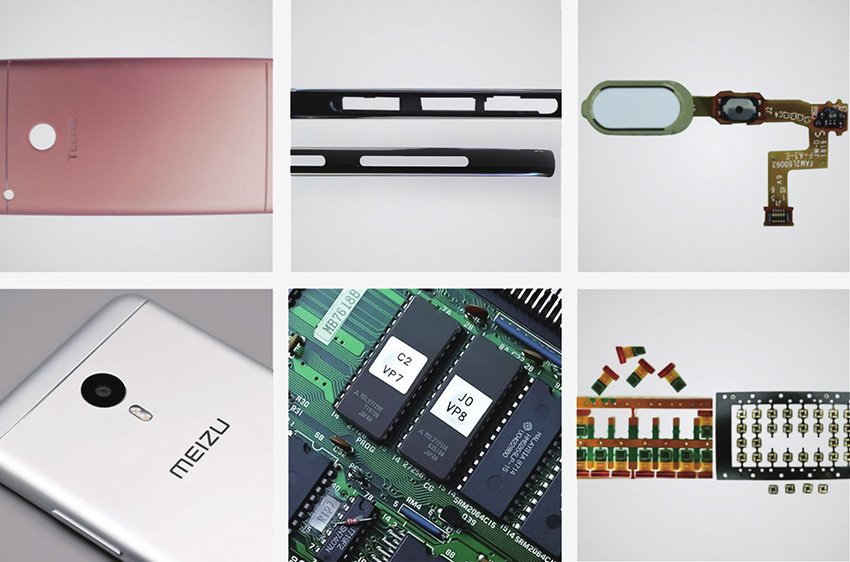

In the mobile phone shell industry, we can find the shadow of laser marking everywhere. Logo marking, mobile phone button marking, mobile phone shell marking, mobile phone battery marking, mobile phone accessories marking, etc., and even inside the mobile phone that you can’t see, there are laser marking of parts. Therefore, unconsciously, laser marking has already entered our lives, bringing beautiful changes to our lives.

Mobile phone shell industry

Solution advantage

1. Laser marking

Laser engraving is to make various symbols, characters, patterns, etc., with extremely fine spots, and the spot size can be in the order of microns. It has a deeper meaning for micro processing or anti-counterfeiting.

The focused ultra-fine laser is like a sharp blade, which can remove the material on the surface of the object point by point. The advantage is that the marking process is non-contact processing, which will not cause negative scratches and friction, and will not cause extrusion or crushing. Therefore, the items to be processed will not be damaged. After the laser beam is zoomed again, the spot becomes smaller, the thermal effect area generated is small, and the processing is accurate, so it can complete some conventional processes that cannot be completed and cannot be achieved.

2. Laser cutting

Laser cutting has become the development direction of modern metal processing technology due to its high speed, high precision, high quality, energy saving and environmental protection. In laser processing applications, laser cutting accounts for 32% of the market share. The difference between laser cutting and other cutting methods is that it has the characteristics of high speed, high precision and high adaptability. At the same time, it also has the advantages of small kerf, small heat-affected zone, good cutting surface quality, no noise during cutting, good verticality of the kerf edge, smooth cutting edge, and easy automatic control of the cutting process. When laser cutting the plate, no mold is needed, which can replace some punching processing methods that require complex and large molds, which can greatly shorten the production cycle and reduce the cost.

3. Sheet metal processing

Sheet metal processing is a key technology that sheet metal technicians need to master, and it is also an important process for sheet metal product forming. It includes traditional cutting and blanking, blanking, bending and forming methods and processes, and various cold stamping dies

With structure and process parameters, various equipment working principles and operating methods, as well as new stamping technology and new processes. The sheet metal processing parts of agricultural machinery products generally use 4-6mm steel plates. There are many types of sheet metal parts and they are updated quickly. The traditional sheet metal processing parts of agricultural machinery products usually use the punching method and the mold loss is large. Usually a large agricultural machinery manufacturer is used The warehouse where the molds are stored is nearly 300 square meters. It can be seen that if the processing of parts still stays in the traditional way, it will seriously restrict the rapid replacement of products and technological development, and the advantages of laser flexible processing are reflected.