In terms of the current market orientation of sanitary products in the country, sanitary products have evolved from pig iron, copper, and zinc alloys to ceramics, plastics, metals and other materials. With the improvement of people's living standards, everyone has higher requirements for sanitary products, not only requiring diversified styles, but also good processing quality.

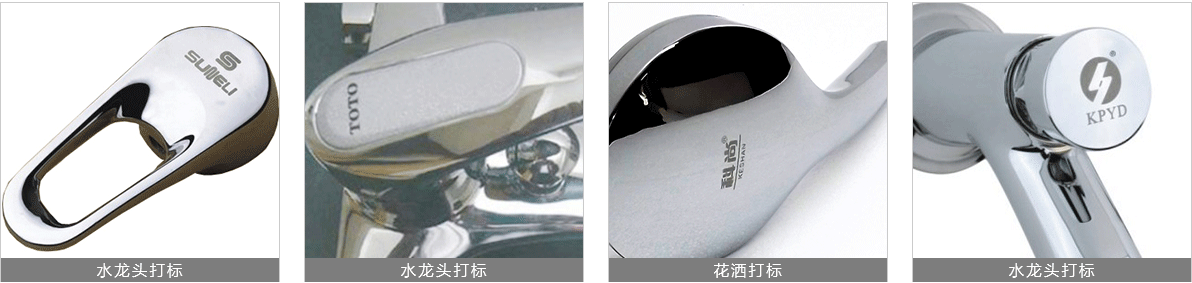

Introduction of laser marking application:

Bathroom products mainly include ceramics, plastics, metals and other materials, but laser marking can meet the high-quality marking requirements of these materials at the same time, including bathroom cabinets, faucets, showers, toilets, bathroom equipment, basins, flush valves, bathtubs and other bathroom accessories Equipment can be marked by laser. Especially in combating counterfeit brands and safeguarding the interests of enterprises and consumers, laser marking can provide strong support for establishing an effective product traceability system for sanitary products.

Advantages of laser marking in the bathroom industry:

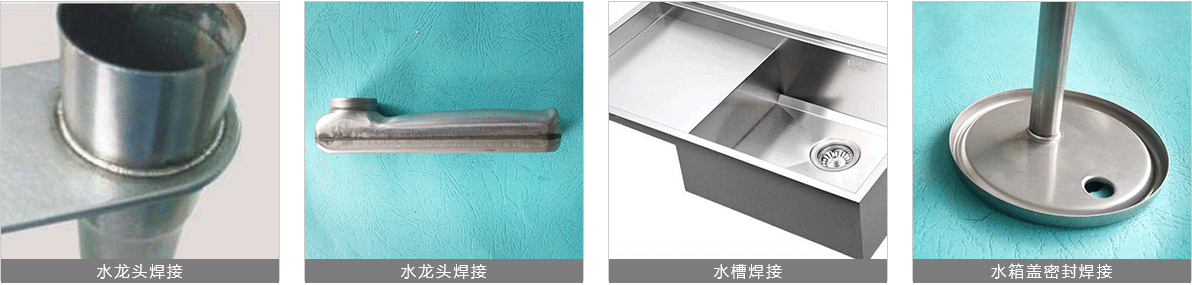

Laser welding application introduction:

Modern stainless steel sanitary ware manufacturing has higher and higher requirements for welding strength and appearance effects, especially parts with high added value and extremely high welding quality requirements, which can be completed without subsequent processing or with minimal subsequent processing. However, traditional welding methods will inevitably cause problems such as distortion of the workpiece due to the extreme heat input.

Compared with traditional welding, laser welding has obvious advantages, but laser welding has higher requirements for the front processing accuracy of the workpiece and the fixtures. To maximize the advantages of laser welding, reduce production costs and provide production efficiency, the entire stainless steel production process needs to be optimized.

Advantages of laser welding in the bathroom industry: